Pushing the Limits: Cutting with Silverline Tools on the SYIL L3 LTY

Cooking on Gas with CERATIZIT & the SYIL L3 LTY

There’s nothing quite like kicking off a Friday morning with precision, speed, and chips flying — and that’s exactly what we were doing by 10am at the SYIL CNC UK Ltd Tech Centre.

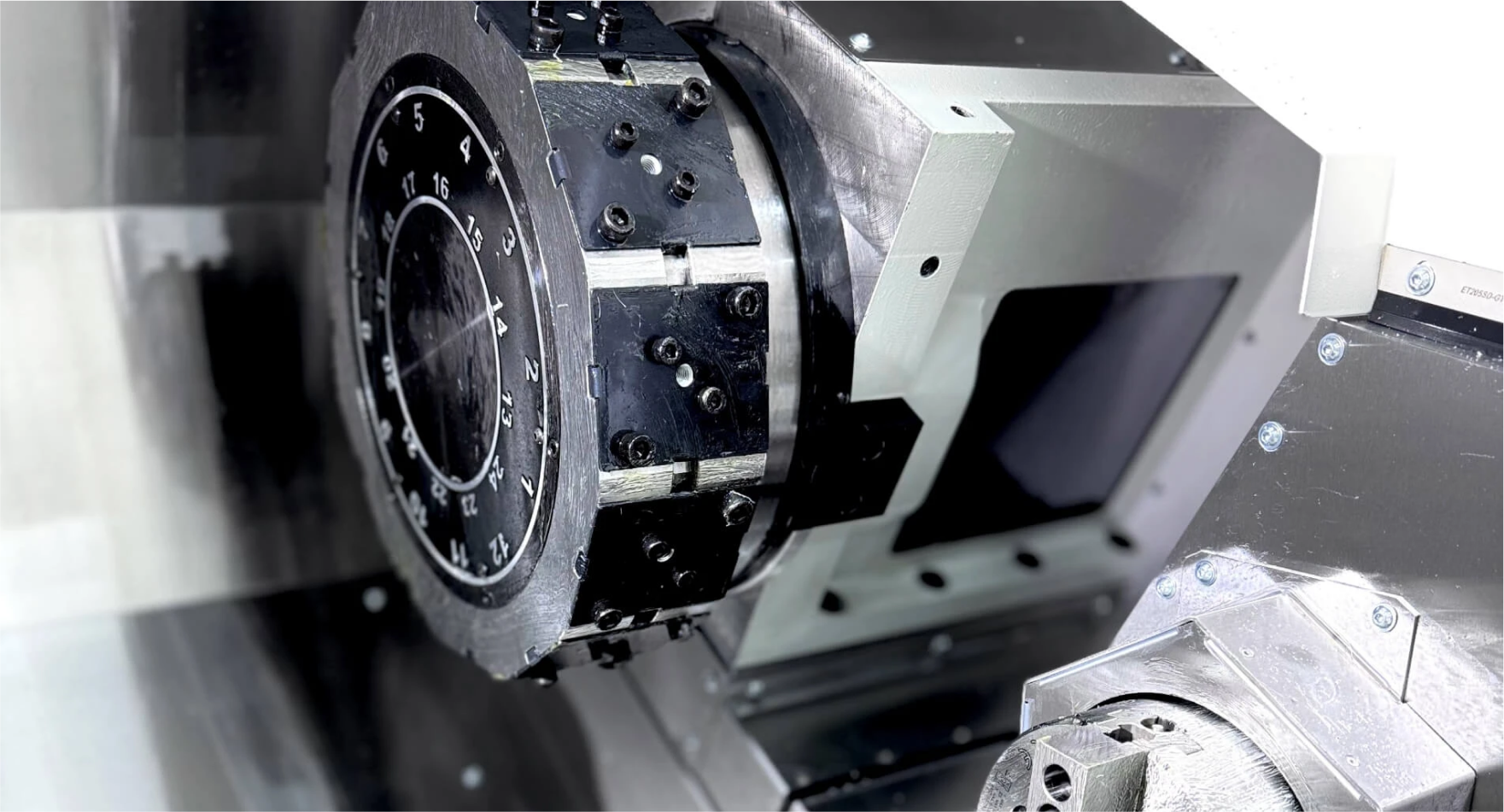

In a live test session, we put the CERATIZIT UK & Ireland Silverline range through its paces on the SYIL L3 LTY — our powerful compound Y-axis turning centre. The goal? To prove just how much performance you can squeeze out of this tooling combination.

In Cut for 3 Hours - Still Going Strong

Believe it or not, this 10mm Silverline tool has been in cut for nearly three hours of touch-time — and it’s still going like a dream.

Even more impressive: it’s confidently breaking through thin-walled sections without chatter or distortion. The result? Clean finishes, solid tool life, and zero compromise on part integrity.

Powered by a Precision Toolchain

This test run was made possible thanks to a high-performance tool and software stack:

-

SYIL L3 LTY – Featuring a 5000 rpm driven-tool compound Y-axis

-

WTO driven tooling, supplied by Cutwel Ltd – for rigidity and cutting accuracy

-

i-Machining strategies by Solid Solutions – for intelligent toolpath control

-

CERATIZIT Silverline 10mm – for endurance, speed, and fine surface finish

It’s a powerful combination that showcases what’s possible with modern turning technology, smart CAM strategies, and high-quality tooling — even on complex parts.

Why It Matters

Whether you’re in subcontract machining, aerospace, motorsports, or general precision turning, this demo proves the SYIL L3 LTY can handle demanding cuts with finesse — all in a compact, cost-effective package.

The ability to run long cycle times with minimal tool wear and high-speed Y-axis interpolation opens new possibilities for shops looking to maximise productivity on a smaller footprint.

Want to Learn More About the SYIL L3 LTY?

This compact turning centre offers C/Y-axis capabilities, driven tooling, and live spindle options — making it ideal for precision turning shops across the UK.